Welcome to Topwell Metal

Whatsapp:8615852509385 Email : [email protected]

Strip Processing

|

A steel plate with a thin thickness, a narrow width, and a long length. Its width is generally 20mm-200mm. Supplied in rolls, its specifications are expressed in thickness×width. According to the quality of the steel, it can be divided into high-quality and ordinary strip steel; according to the rolling method, it can be divided into two types: hot-rolled and cold-rolled, which are called hot-rolled strip and cold-rolled strip respectively. The thickness of common hot-rolled steel strip is 2mm-6mm, and the thickness of cold-rolled steel strip is generally 0.05mm-3.60mm. Strip steel can be made of common carbon steel, carbon steel, spring steel, tool steel, stainless steel and other steel types. Widely used in the manufacture of welded pipes, clamps, washers, spring blades, saw blades, blades, etc. |

For easy welding or connecting, our clients usually ask us to do the bevel edge chamfering process for stainless steel sheets. Edge chamfering machine,which can quickly chamfer both sides of stainless steel sheets at the same time and achieve a good

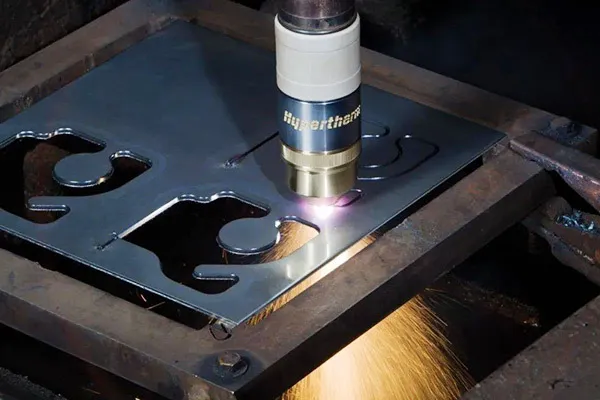

Plasma cutting is commonly used in producing steel parts for engineering, wind turbines, infrastructure, and motor vehicles(transport, agricultural, and other specialty vehicles) (also for various other materials). Plasma cutting is used in these ind

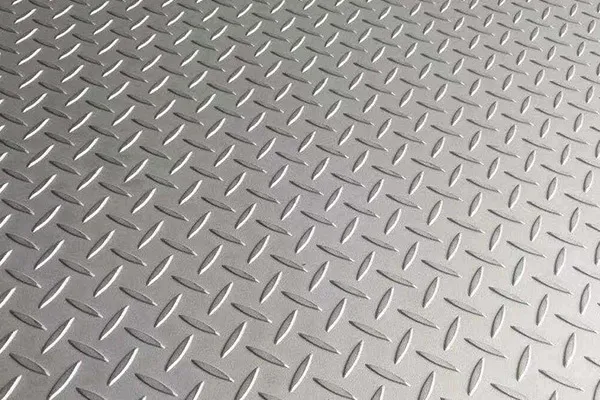

Knurling is a finishing process in metal material processing that creates a groove or pattern on the surface of a stainless steel sheet. It achieves by a rotary tool that presses the desired embossing pattern into the metal. Knurling is a decorative

Under the pressure of the bending machine, the stainless steel sheet first undergoes elastic deformation, then enters plastic deformation. At the beginning of the plastic bending, the steel sheet is free to bend. With the upper or lower molds applyin

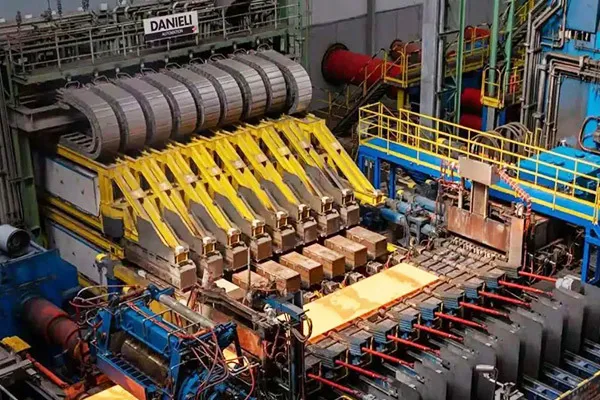

The metal billet is passed through the gap between a pair of rotating rolls (various shapes), and the cross-section of the material is reduced and the length is increased due to the compression of the rolls. This is the most commonly used production

Topwell steel experience in polishing stainless steel surfaces began in 2011, initially as a polishing service for neighboring stainless steel distributors and manufacturing workshops. As demand has increased dramatically, polished stainless steel she

Waterjet cutting high-pressure water jet cutting technology is a machine that uses high-pressure water flow to cut. All workpieces can be carved at will under the computers control, and will not be affected by the texture of the material. Because of

Stainless steel brushing refers to the surface treatment process that stainless steel surface processing like a filamentary texture grain effect. Its surface is matte. Looking closely, you can see a hint of the grain on the stainless steel surface bu

A steel plate with a thin thickness, a narrow width, and a long length. Its width is generally 20mm-200mm. Supplied in rolls, its specifications are expressed in thicknesswidth. According to the quality of the steel, it can be divided into high-quali

Main advantages of laser cutting: Great Flexibility It can cut one stainless steel sheet in many different ways without changing tools. In addition, it can cut a variety of complex shapes. Accuracy With an accuracy of +/- 0.1 mm, laser cut parts can

We will use the most suitable stainless steel coil or sheet as the original material through precise calculation according to your dimensional requirements, thus avoiding scrap. Compared with cross shearing and longitudinal shearing, custom shearing

GET a Quote

×

loading...