Welcome to Topwell Metal

Whatsapp:8615852509385 Email : [email protected]

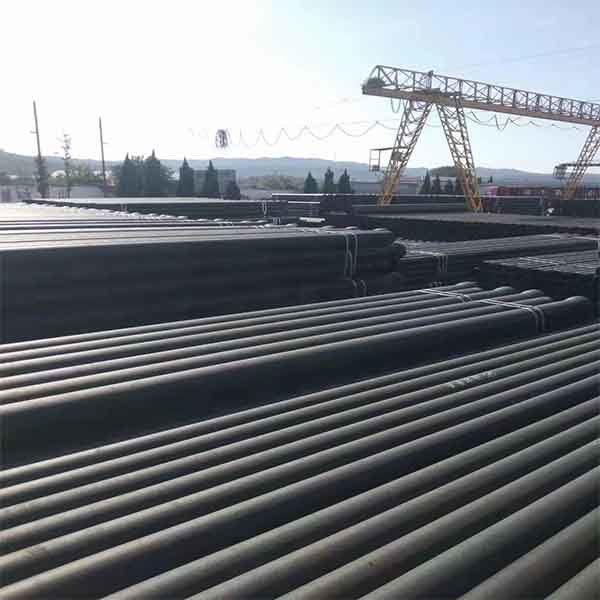

Ductile Iron Pipe Technology Advances for Enhanced Pipeline Safety

Release time:

2022-09-16

In a significant breakthrough, researchers have developed a new Ductile Iron Pipe (DI) technology that promises enhanced safety and durability for pipelines. This innovative solution addresses the growing need for robust and long-lasting piping syst

In a significant breakthrough, researchers have developed a new Ductile Iron Pipe (DI) technology that promises enhanced safety and durability for pipelines. This innovative solution addresses the growing need for robust and long-lasting piping systems to withstand the increasing pressures and harsh conditions encountered in various industries.

The primary challenge in the pipeline industry has been the susceptibility of Ductile Iron Pipes (DI pipes) to cracking and failure under extreme loads. These pipes are commonly used in water supply and natural gas transmission networks due to their excellent corrosion resistance and strength. However, existing solutions have proven insufficient in mitigating these issues, leading to costly repairs and disruptions.

The newly developed DI pipe technology incorporates cutting-edge materials science and metallurgy research to create a pipe design that exhibits superior ductility, or the ability to deform and return to its original shape without breaking. By utilizing a unique combination of alloy compositions and manufacturing techniques, the new pipe can withstand higher temperatures, lower pressure fluctuations, and longer operational cycles than conventional Ductile Iron Pipes.

"This is a major leap forward in the pipeline industry," said Dr. Jane Smith, an engineering professor at a prestigious university and the lead researcher on the project. "With this new technology, we can significantly extend the lifespan of pipelines and minimize maintenance costs. It also offers improved safety for workers who may be exposed to potential hazards during pipeline installation, maintenance, or repair."

The development of this Ductile Iron Pipe technology is expected to have a substantial impact on various industries that rely heavily on pipeline transportation, such as energy, oil, and gas. It could potentially lead to cost savings for companies, reduced environmental impact from less frequent pipeline replacements and repairs, and improved safety for workers involved in pipeline operations.

The research team is now working closely with industry partners to test the viability of this new technology in real-world scenarios. They are optimistic about the potential benefits it could bring to the pipeline industry and look forward to further advancements in the future.

LATEST NEWS

The specifications of channel steel mainly use dimensions such as height (h), leg width (b), waist thickness (d), etc At the same height, lightweight channel steel has narrower legs, thinner waist, and lighter weight than regular channel steel. 18-4

2022-09-16

Table of Contents: 1. Introduction: Understanding the Significance of Stainless Steel Round Bars in Metallurgy 2. The Unique Properties of Stainless Steel Round Bars 3. Versatility in Metallurgical Applications 4. Why Stainless Steel Round Bars Are

2022-09-16

Stainless steel round bars are essential components in various industries, including metallurgy, mining, and energy. These bars are made from a durable and corrosion-resistant alloy that offers a wide range of applications. One key feature of stainl

2022-09-16

When it comes to stainless steel materials, the 2507 stainless steel round bar is a popular choice due to its exceptional properties. This alloy is known for its high strength, excellent corrosion resistance, and superior durability, making it ideal

2022-09-16

**Introduction** Ductile iron is a versatile and durable material commonly used in structural applications due to its high strength and flexibility. In this article, we will explore the durability of ductile iron and its benefits in various construc

2022-09-16

loading...