Welcome to Topwell Metal

Whatsapp:8615852509385 Email : [email protected]

904L Stainless steel coil

Keyword:

Ductile Iron Pipe

PRODUCT DETAILS

904L stainless steel coil (super austenitic stainless steel) is a high alloyed austenitic stainless steel with very low carbon content. It has good corrosion resistance in dilute sulfuric acid and is specially designed for environments with severe corrosion conditions. It has high chromium content and sufficient nickel content. The addition of copper makes it have strong acid resistance, especially high resistance to chloride interstitial corrosion and stress corrosion cracking. It is not easy to appear corrosion spots and cracks. Its pitting resistance is slightly better than that of other steels. It has good processability and weldability, and can be used for pressure vessels.

|

Name |

904L Stainless Steel Coil |

|

Standard |

JIS, AiSi, ASTM, GB, DIN, EN |

|

Material |

904L |

|

Surface Treatment |

BA/2B/NO.1/NO.4/4K/HL/8K/EMBOSSED or according to customer requirementg,etc. |

|

Width |

100mm-2500mm or as required |

|

Thickness |

0.1mm-4mm or as required |

|

Length |

As customer's request |

|

Inspection |

Fully accept all the third party to test before shipment. |

|

Packing |

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required. |

|

Payment Terms |

L/C, T/T ETC. |

Stainless steel coil is a thin steel plate supplied in coils, also called strip steel. There are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.

Manufactured from high-grade 904L stainless steel, this coil offers unparalleled corrosion resistance, even in the most aggressive conditions. It is highly resistant to pitting, crevice corrosion, and stress corrosion cracking, making it the preferred choice for industries such as chemical processing, marine, and offshore.

The 904L stainless steel coil is known for its exceptional strength and toughness. With a high nickel and chromium content, it exhibits superior resistance to acids, alkalis, and chloride-containing environments. This makes it a reliable option for use in harsh chemical environments and applications where resistance to corrosion is critical.

Thanks to its low carbon content, the 904L stainless steel coil provides excellent weldability, ensuring fabrication and installation. It can be seamlessly integrated into various systems, such as heat exchangers, condensers, and desalination plants, delivering reliable performance under high-pressure and high-temperature conditions.

One of its unique selling points is its exceptional resistance to sulfuric acid. This feature makes the 904L stainless steel coil a top choice for industries involved in the production of sulfuric acid, such as fertilizer manufacturing and oil refining. Its ability to withstand aggressive environments and provide long-term reliability sets it apart from other stainless steel coils on the market.

Furthermore, the 904L stainless steel coil offers excellent formability, allowing for intricate designs and custom shapes. It retains its aesthetic appeal even after prolonged exposure to harsh elements, making it suitable for architectural and decorative applications.

Investing in the 904L stainless steel coil guarantees exceptional value and longevity. Its superior corrosion resistance, strength, and versatility make it a reliable and cost-effective solution. With this coil, you can have confidence in the performance and longevity of your projects, regardless of the challenging conditions they may face.

Choose the 904L stainless steel coil for premium quality, unmatched durability, and exceptional resistance to corrosion. Upgrade your materials to the best in the industry and experience the difference.

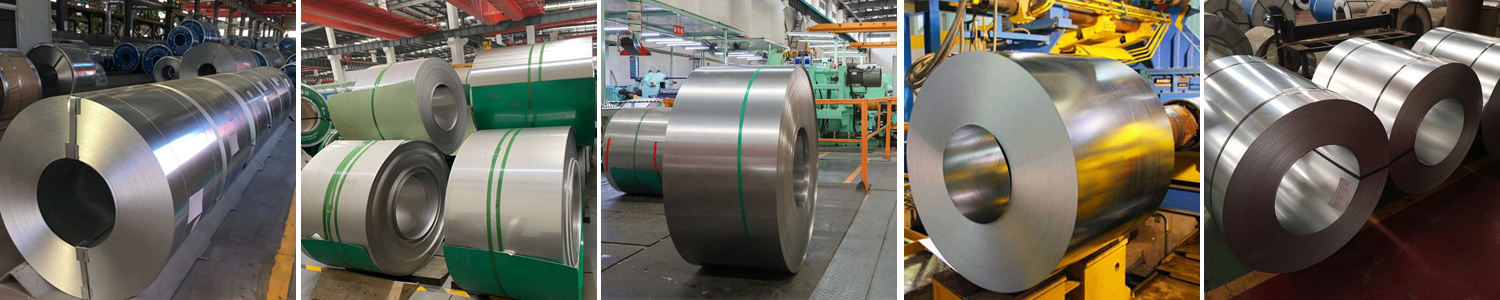

Warehouse Storage

Our company is committed to providing a series of high-quality, innovative and cost-effective steel products, which are widely used in various industries. With more than 3,000 independent patents, the annual output of steel products exceeds 5 million tons, and the inventory exceeds 200,000 tons.

Packing and shipping

Due to our continuous and widespread success in overseas market and outstanding social contributions, our company was awarded by the local government for many times. Our products have been exported to Southeast Asia, Middle east, South America, Europe, Oceania and other countries and regions, which enjoys good reputation.

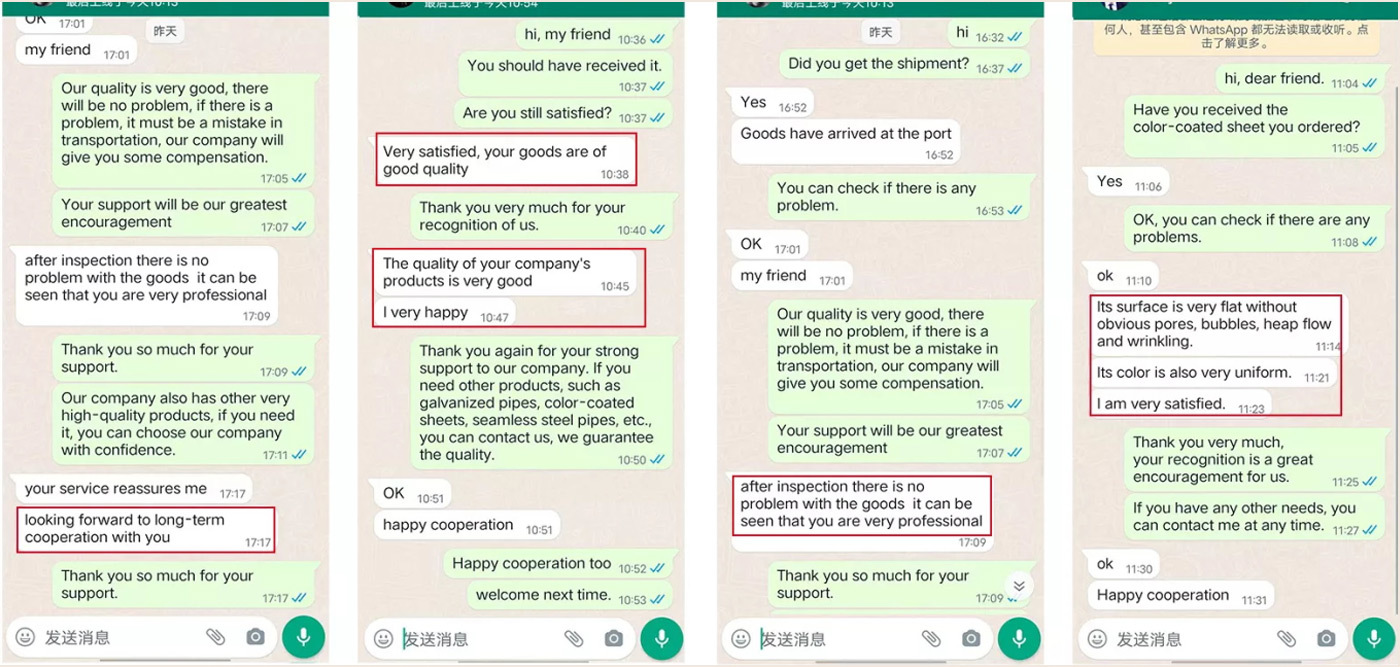

Customer conversation

We adhere to the management principle of "quality first, service first, continuous improvement and innovation to meet customer needs", and strive to build a leading world-class manufacturer in China.

Application field

Construction and decoration field, cooking equipment, kitchenwares, household appliances, food processing equipment, hospital surgical equipment, shipbuilding, oil industry, refrigeration equipment, papermaking industry, pressure vessel, chemical equipment, bridge construction, textile printing and dyeing equipment.

Partners

FAQ

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: Do you provide the samples? Free or Extra?

A: The cost of the samples is according to the value.The cost of the freight is necessary.

Q: Do you have large amount of steel products in stock?

A: Yes , we have a large-scale indoor warehouse with perennial spot stocks totally above 200000 tons.

Q: What is your delivery time and the supply ability?

A:The delivery time normally within 15~28working days,we can supply about 10,000tons every month.

Q: How to order?

A: Buyer sends the enquery --> Buyer gets the quotation --> Order confirmation --> Buyer send the deposit --> Seller prepares goods --> Seller makes the strict inspection --> Buyer Arranges Balance Payment --> packing and delivery

Q: How can you ensure the quality of your product?

A: All products have to go through three checks in the whole manufacturing process,it includes production and Random Testing in warehouse and Before Shipping.

GET A FREE QUOTE

loading...